What is Bacterial Biofilm?

Biofilms are naturally occurring complex communities of micro-organisms. They start by free-floating individual 'planktonic' bacteria cells attaching to a surface in a wet environment. 'Bacterial Biofilm' is the first step in a microbial colony. Only certain bacteria have the ability to attach and form initial biofilms. Where favourable conditions exist planktonic bacteria will attach and quickly proliferate.

The first cells attach to surfaces using their adhesion features - Fimbrea, Pili and a Polysaccharide (slime) layer. Once anchored the growing multicellular community communicate between cells by Quorum Sensing. Together they begin to exude a hydrogel, a sticky slime known as “Extracellular Polymeric Substances” (EPS). The slimy layer is often felt on the surfaces of containers of static water after just a few days. The hydrophobic EPS gel provides increasing levels of protection for the growing biofilm community and improves adhesion to the surface. Within the colony millions of single cell bacteria take up different roles. Together they act much like a multi-cellular organism, including the exchange of DNA. Enabling adaptions to develop rapidly, such as antibiotic resistance. Some cells eventually break away from the colony. Once detached those now mobile cells float downstream to quickly spread infections to new locations.

As a core biofilm develops, members of the increasingly complex community gain protection from turbulence, heat, cleaning chemicals, biocides, anti-microbial agents and antibiotics. Biofilms can be extremely difficult to kill or remove once they become established in a system. Eventually a hard protective outer plaque layer can even form. Coating and blocking membranes, tanks, pipework and machinery. On a smaller scale it is seen as dental plaque on teeth. Inside the biofilm plaque corrosive excreta from the organisms accumulates. Damaging equipment such as heat exchangers by 'MIC' - Microbiologically Induced Corrosion. These acids causes dental cavities.

The effects of Biofilms are wide reaching. If allowed to develop biofilm matrices become havens for other unicellular and multicellular micro-organisms. Allowing numerous other species of bacteria, yeasts, fungi, amoeba, protozoa, etc. to proliferate; even harbouring viruses. Each colony is unique. Unless controlled, biofilms facilitate the spread and persistence of pathogens, waterborne diseases and toxins

in any water rich environment.

Why do I need a Biofilm Sensor?

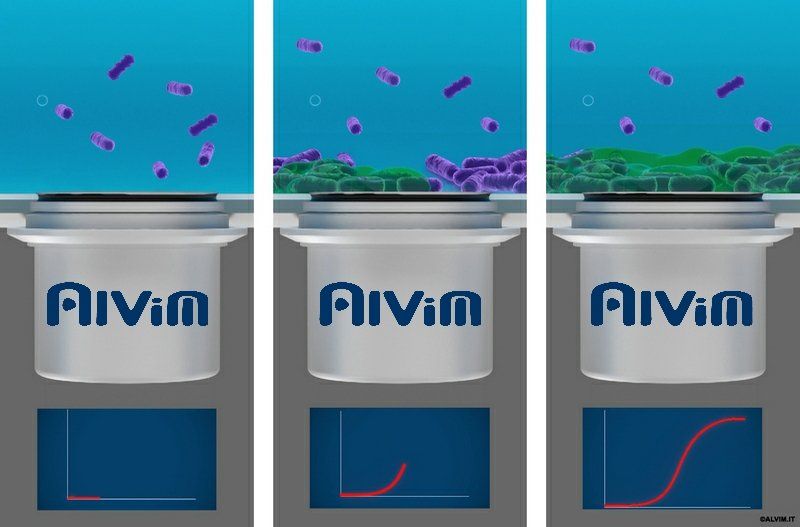

ALVIM Biofilm Sensing Probes

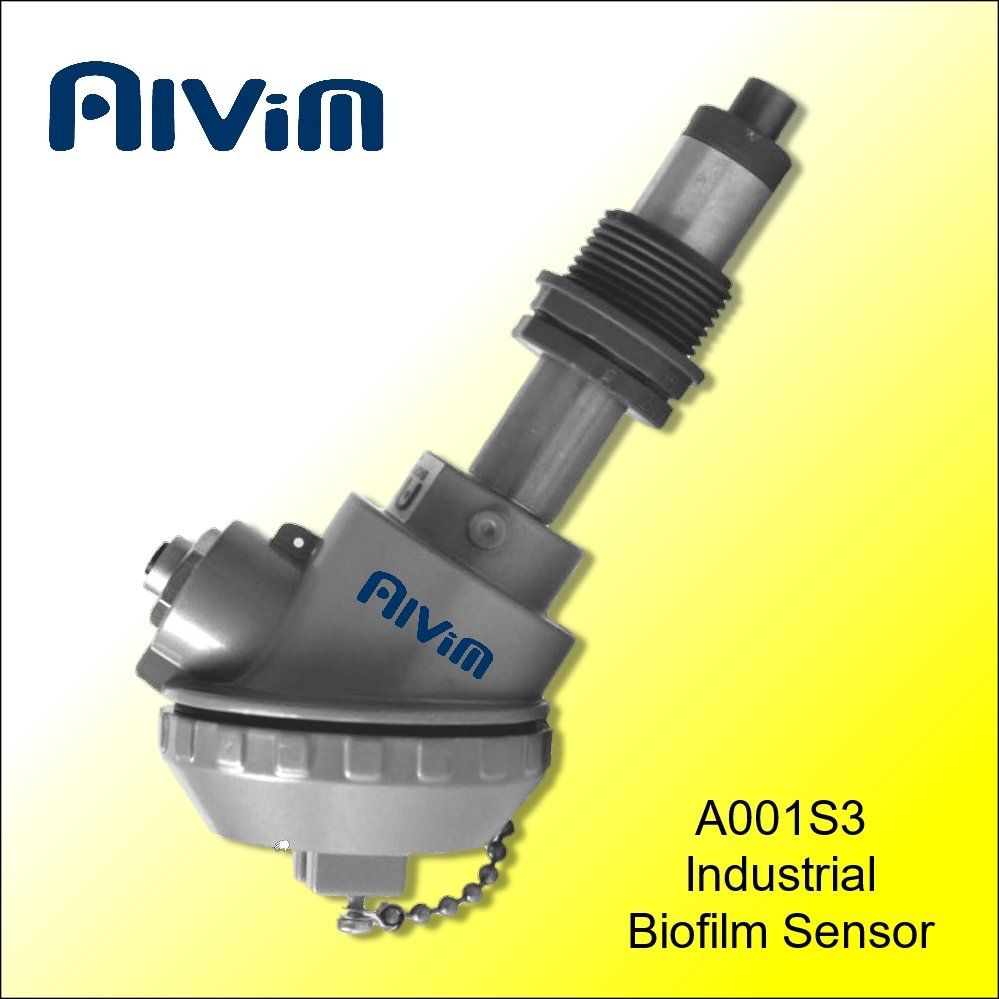

ATEX Biofilm Sensors

ATEX Biofilm Sensors.

Certified to Ex II 2G. Suitable for applications in explosion risk environment, including the oil, gas, biofuel and chemical sectors

Example: Legionella in Hospital Water

Control of Legionnaires’ Disease in Water and Evaporative Cooling Systems - A legal requirement!

"Legionellosis is the collective name given to the pneumonia-like illness caused by legionella bacteria. This includes the most serious legionnaires’ disease, as well as the similar but less serious conditions of Pontiac fever and Lochgoilhead fever. Legionnaires’ disease is a potentially fatal form of pneumonia and everyone is susceptible to infection" UK Health & Safety Executive

The Legionella pneumophila

bacteria infects and develops in water systems

inside amoeba. Amoeba eat biofilm!

Therefore in principle:

No Biofilm = No Amoeba = No Legionella

In the UK landlords and employers are legally required to eliminate or control Legionella. Particular attention must be paid to air conditioning systems, cooling towers, evaporative condensers, water systems, humidifiers, indoor fountains, etc.

ALVIM probes respond to Biofilm growth and changes in water conductivity. In effect as well as detecting Bacteria Biofilm Sensors can also provide the significant benefit of continuous indicative REDOX monitoring, e.g. for chlorine or bromine concentrations in cooling towers.

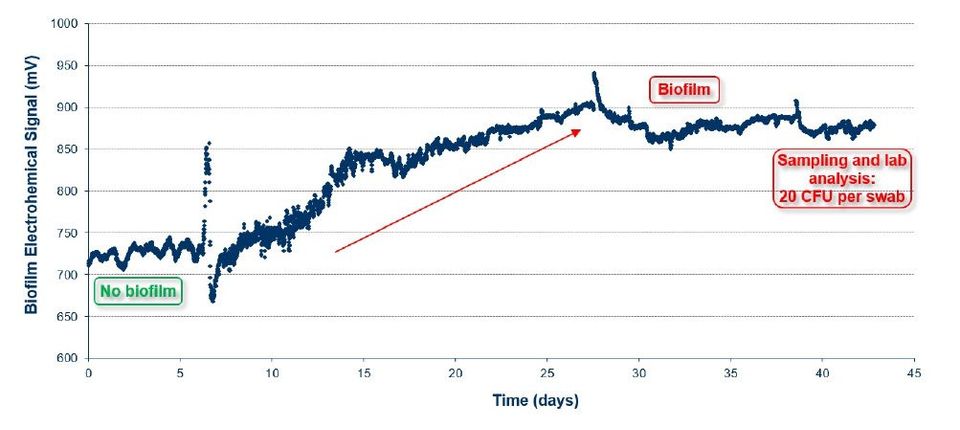

Application Case Report

Safety in Food Production & Processing Systems

Production of Water-based Products

Protection of Critical Water Cooled Systems

Protection of Water Treatment Systems

| Application Sector & Link | Subject of Application Case Report | PDF Report |

|---|---|---|

| Open cooling towers | Biocide effectiveness and elimination of bacteria | Download |

| Industrial Cooling towers | What happens when chlorination fails? | Download |

| Power Plant Water Treatment | Improved heat exchange and power production by controlling biofilm growth | Download |

| Legionella prevention | Biofilm sensor helps prevent hospital water infection | Download |

| Food Production | Detection of bacteria due to failure of sterile filters & UV sanitization | Download |

| Mineral Water Bottling | Biofilm sensors detect ineffective CIP cleaning | Download |

| Soft Drinks Production | Integration of Biofilm Sensors with automated CIP improves process hygiene | Download |

| RO Water Treatment | Biofilm detection allows better biocide scheduling for improved cleaning | Download |

| Membrane Desalination | Improved efficiency of biocide in RO system | Download |

| Paper Production | Biofilm sensor identifies abnormal bacterial growth. Allowing remedial action | Download |